Additive technologies, commonly known as 3D printing, have transformed the way products are prototyped and produced since the 1980s. Software and hardware advances over the last few decades have allowed the technology to grow in amazing ways. Prototyping with additive technologies continues to be one of the fastest and most cost-effective manufacturing methods available. Prototyping and additive technologies are ever changing and so are the means of production. Today, the term Additive Manufacturing (AM) is typically used to described the downstream, production phase of product development.

What is 3D Printing Additive Manufacturing?

Additive manufacturing constructs 3D models by layering materials onto a build plate. The object is made by following specifications laid out by a Computer-Aided Design (CAD) file or a digital 3D model. Additive manufacturing can use a variety of different materials including plastic polymers, metals, glass, ceramics, foams, gels, food, and more. Additive manufacturing applications include industrial tooling, customized products, production parts, and as a visualization tool for design.

There are numerous processes used by additive manufacturing technologies. These include / /

- Vat Polymerization / / The part is made layer-by-layer in a liquid resin photopolymer vat. Ultraviolet (UV) light cures the resin while a platform moves downward after each layer has hardened.

- Sheet Lamination / / Thin sheets are bonded together in layers to form a single part.

- Powder Bed Fusion / / Ultra-fine layers of powder are laid onto a build platform and then bonded by lasers, electron beams, or thermal print heads. Powder Bed Fusion is used in some additive manufacturing techniques including, Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), selective heat sintering, Direct Metal Laser Melting (DMLM), and electron beam melting.

- Material Jetting / / A print head moves along X-, Y-, and Z-axes to distribute photosensitive material, layer-by-layer, on to a build plate. UV light is used to cure the material as it is jetted.

- Binder Jetting / / A binder is deposited onto a powder bed, bonding layers one at a time. Can be used for metal, sand, and ceramic in powder/granule form.

- Directed Energy Deposition / / A laser mounted to a 4- or 5-axes arm melts filament feedstock or powder.

- Material Extrusion / / A heated nozzle distributes a spool of the thermoplastic polymer in a continuous stream while depositing the material, layer-by-layer, to build a part.

Additive Manufacturing Benefits

Additive manufacturing can be the right choice if you are searching for economical project solutions. Additive manufacturing has many advantages over conventional manufacturing. The right material and a single device can make a measurable impact on the product development process. Bring your product to market at a rapid pace with additive manufacturing. Functional integration and adaptations can be directly designed into the product, reducing the number of development cycles. Review the benefits of additive manufacturing / /

- Replace Complicated, Traditional Processes

- Reduce Product Development Time

- Produce Lightweight Parts

- Create Parts with Custom and Complex Geometries

- Build High-Quality Visual and Functional Prototypes

- Lower Costs Compared to Traditional Manufacturing

Same Day and Next Day 3D Printing

Fathom’s additive manufacturing services allow customers to go from design to a physical part in as quickly as same day. Fathom offers PolyJet printing for same-day pickup or shipment to meet tight deadlines. Need it tomorrow? Fathom’s next-day 3D services include PolyJet, Fused Deposition Modeling (FDM), and Stereolithography (SLA). All of these technologies — FDM, PolyJet, and SLA — are perfect for projects that require high resolution and excellent surface finish with the durability of engineering-grade thermoplastics. At Fathom, we understand the importance of deadlines and are ready to help cross that project off your list. Learn more about our same day and next day services.

PolyJet Parts in As Soon As Same-Day / / Get A Quote

Large Prototypes

Fathom can make large prototypes to help demonstrate and test new designs. A large prototype gives customers the chance to discover any design issues early in the product development process before investing time and money in large-scale production. Present the over-sized prototype to clients to see if the product is user-friendly and to gather valuable customer satisfaction data. Large prototypes may also be used as a visual model for investors – providing that final, hands-on push for capital. Your team will also gain valuable insight into the manufacturing process and determine which method is the best fit while estimating production costs. Learn more about large prototypes.

3D Printing vs. Injection Molding

3D printing and injection molding are significantly different manufacturing processes. 3D printing is an additive manufacturing method that builds parts layer-by-layer. 3D printing is a good fit for projects that require a lower volume of products, projects with complex and intricate designs, and any project that may require quick changes early in the product development cycle.

Injection molding utilizes a metal mold and molten plastic resin to make parts. The molten material is injected into the metal mold. The part is removed from the mold after the material has cooled. Injection molding is ideal for large volume production runs, components that are not complex or delicate, and parts that require enhanced strength. The large production runs can make injection molding a very economical choice despite significant upfront costs. Learn more about 3D Printing vs. Injection Molding.

3D Printing Quotes

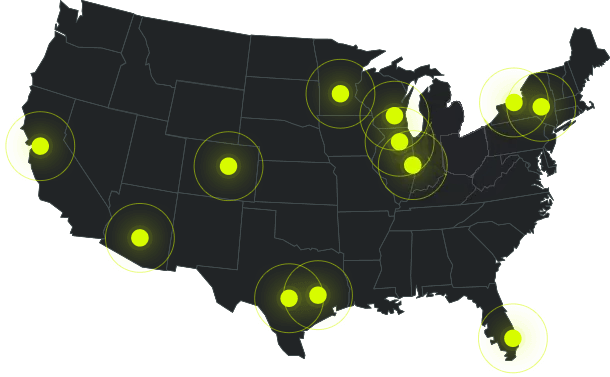

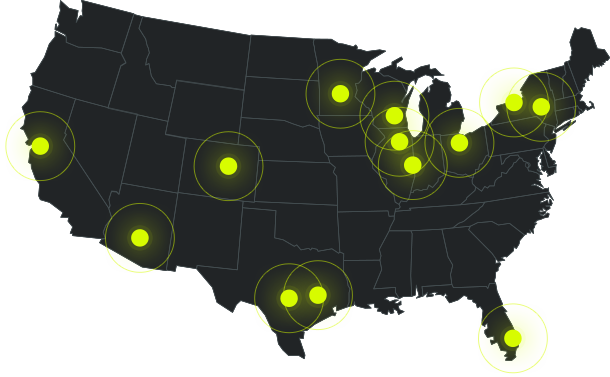

Use Fathom’s online SmartQuote platform to receive your instant 3D printing quote. Fathom has served nine out of the top 10 Fortune 500. Fathom can tackle projects of different levels of complexity, technology option, or size. Getting a quote is a simple, three step process. First, select your preferred technology — additive or traditional. Second, upload your file to the instant online quote tool. Select your preferred materials, finishes, and quantity. Finally, submit your quote for pricing and shipping options. Fathom offers expedited services in same-day, next-day, two-day, three-day, or more options. Additive manufacturing technologies include Selective Laser Sintering (SLS), PolyJet, Fused Deposition Modeling (FDM), Stereolithography (SLA), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Learn more about getting a 3D printing quote.

Low-Volume Production

Fathom offers multiple low-volume manufacturing methods, allowing designers to create high-quality parts with precision, excellent finish, and short turn around times. Traditional manufacturing methods may experience longer lead times and higher material costs when compared to additive manufacturing. Many companies take a hybridized approach to production in order to capitalize on the strengths of both conventional and additive manufacturing. Fathom’s manufacturing technologies are the perfect solution for bridge production or low-to-medium volume runs. Services include injection molding, CNC machining, and 3D printing. Fathom is faster, more flexible, and more economical than the competition when it comes to projects that require a lower volume. Learn more about low volume production.

Rapid Prototypes

Rapid prototyping is the process of creating a physical part from a CAD file. The resulting rapid prototype can be used to test the product design functionality or efficiency before the part is reproduced in larger volumes. Additive manufacturing methods allow companies to quickly create a rapid prototype. The benefits of rapid prototyping include the ability to gather valuable feedback from clients and investors, receive funding, and make changes early in the product development cycle. Rapid prototypes can also reduce waste, save time, and effectively communicate concepts. Rapid prototypes are ideal to test fit, size, and overall appearance.

3D Printing Materials

Plastic polymers, metals, and ceramics are the primary types of materials used for 3D printing. Additional materials may include different types of paper, food, or polymer adhesive sheets. Common polymers for 3D printing include Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate (PC). Polymers can be combined to create a range of other materials that have different structural and aesthetic properties. 3D printed metals include steel, titanium, aluminum, and cobalt chrome alloy. 3D printed ceramic materials are porcelain, silicone-carbide, and silica/glass. The proper material must be matched with the appropriate additive manufacturing technology. Fathom can deliver high-quality parts with any of the additive manufacturing technologies listed below. Learn more about 3D printing materials.

3D Printing Services Available

Fathom offers six different additive manufacturing processes, including SLS, PolyJet, FDM, SLA, MJF, and DMLS or Metal 3D Printing. All of these processes have different capabilities and limitations. Fathom’s online quoting tool, SmartQuote, can help you explore pricing and get instant quotes.

Additive Manufacturing Materials by Technology

Fathom offers a comprehensive mix of materials for additive manufacturing. Selecting the best technology and material for your unique part is critical to producing a viable product. Fathom offers six additive manufacturing technologies that each offer a diverse range of material options. Fathom will work directly with you to determine the best technology and material for your next project. Talk to a Fathom expert today.

PolyJet (PJ) 3D Printing

What is Poly Jet? PolyJet technology is a 3D printing process that can achieve smooth surfaces, thin walls, and complex geometries all while holding tolerances as tight as 0.1 mm. PolyJet is the only 3D printing technology that supports a wide variety of materials with physical properties that range from rubber to rigid and appearance from transparent to opaque. PolyJet is commonly used for prototyping and is best for projects that require accuracy, finish, and detail.

How does a PolyJet printer work? The PolyJet printer operates like an inkjet printer, but instead of using drops of ink, the printer extrudes drops of photopolymers. The drops are placed, layer-by-layer, until the part is finished. Each layer is cured under UV light as it is extruded allowing the part to be used immediately after printing. Like most 3D printing technology, the layers are printed onto a build platform. Support gel is used when intricate designs or complex geometries are desired. The gel is easily removed by soaking the part in water or with water jetting.

Is PolyJet the same as Stereolithography (SLA)? PolyJet and SLA are similar manufacturing processes with several notable differences. PolyJet and SLA both use UV light to cure the resin, however, that is where the similarities end.

PolyJet printers extrude droplets of photopolymer resin onto a build platform. PolyJet builds the part upward off of the build plate as the printer moves away from the build plate. SLA uses a vat of resin and a UV laser. The build plate is lowered into the vat of resin. The laser is then pointed into the vat. The laser traces the shape of the part. Any resin hit by the laser will solidify onto the build plate. The build plate is then lowered and the process starts again. SLA parts are also built in the upward direction as the build plate moves away from the laser.

Both PolyJet and SLA utilize support material in order to print designs with complex geometry. PolyJet printers use a gel material for the support. The gel is water-soluble and will wash away with soaking or water jetting. SLA printers use breakaway support material that must be removed by hand. The SLA manufacturing process is done in a vat of liquid. All SLA printed parts will need to be washed after completion to remove any liquid resin residue. This washing can increase post-processing costs. PolyJet printed parts do not need to be washed after the manufacturing process has concluded but soaking may be needed to remove the support gel.

PolyJet Advantages / /

- Produce Intricate Designs, Complex Details, and Precise Features

- Utilize a Variety of Colors and Materials into One Model for Increased Efficiency

- Make Accurate Jigs, Fixtures, Molds, and Other Tools

- Create Detailed and Smooth Prototypes that Simulate the End Product

- Experience Rapid Build Times

- Provides Good Tensile Strength

- Offers a Wide Range of Materials

PolyJet Applications / /

- Medical / / Organ Replicas, Prosthetic Limbs, and Joint Replacements

- Dental / / Crowns, Bridges, and Other Orthodontics

- Consumer Goods / / Rapid Prototyping, Injection Modeling, and Functional Prototyping

PolyJet Parts In As Soon As Same Day / / Get A Quote

Stereolithography (SLA) 3D Printing

What is the Stereolithography? Stereolithography technology is ideal for medium- to large-sized parts in need of high-resolution finishes. SLA is an extremely cost-effective solution for creating durable, aesthetically pleasing parts. SLA offers scalability due to the sizes of the machines, which allows the production of parts of considerable size. SLA is designed for parts that only require one material. Unlike PolyJet, every component of an SLA part must be made from a single material. There are also fewer material choices for SLA when compared to PolyJet.

How does an SLA printer work? SLA uses a bath of resin and UV laser beams to create parts. The laser traces a shape, dictated by the CAD file, across the surface of a resin bath. The resin touched by the laser hardens. The build platform then descends in the resin bath and the process is repeated until the entire part is complete. A chemical bath is then used to clean the part. All parts made with SLA must be washed after completion. The part is ready to be used after cleaning.

What is the difference between Stereolithography and 3D printing? Stereolithography is a methodology of 3D printing. It is one of the earliest used methods of 3D printing technology. Chuck Hull patented SLA in 1984 as a process to create 3D objects by using thin layers and then curing those layers using UV light.

Stereolithography Advantages / /

- Great for High-Resolution Finishes

- Minimal Variances

- Accurate and Durable Parts

- Rapid Production

- Strong Enough to be Machined

Stereolithography Applications / /

- Medical / / Create 3D models of anatomy, aid for diagnosis, preoperative plans, and implant design

SLA Parts In As Soon As Next Day / / Get A Quote

Fused Deposition Modeling (FDM)

What is Fused Deposition Modeling? Fused Deposition Modeling (FDM) technology is an ideal fabrication method for all kinds of applications. FDM utilizes a wide range of engineering-grade thermoplastics to create concept models, functional prototypes, and end-use parts such as final goods and manufacturing aides (e.g., jigs and fixtures).

How does a FDM printer work? FDM is a filament-based additive technology. Material is distributed by a moving print head that extrudes a heated thermoplastic in a pattern, layer by layer, onto a build platform. This technology includes the use of support material to create supportive structures that are removed by force or in solution. During printing, the support and molding material takes the form of filaments, or threads, that are fed through a nozzle. The filament is then extruded onto the build platform. A computer controls the nozzle movements and the build platform position. Production time depends on the size of the object being produced.

What materials are used in FDM? The most common material used for FDM is Acrylonitrile Butadiene Styrene (ABS). Other materials used in FDM include Thermoplastic Polyurethane Elastomer (TPU), Antero™ 800NA (polyetherketoneketone), ULTEM™ 1010 resin (polyetherimide), ULTEM 9085 resin (polyetherimide), and similar thermoplastics.

Fused Deposition Modeling Advantages / /

- Greater Design Freedom

- Faster Lead Times

- Quick Post-Processing Without Using an Organic Solvent

Fused Deposition Modeling Applications / /

- Production Parts

- Jigs and Fixtures

- Functional Prototypes

- Food and Drug Packaging

- Other Applications Requiring Tight Tolerances, Toughness, and Environmental Stability

FDM Parts As Soon As Next Day / / Get A Quote

Multi Jet Fusion (MJF) 3D Printing

What is Multi Jet Fusion (MJF)? Multi Jet Fusion technology is a relatively new additive manufacturing technology. Like other 3D printing technologies, MJF builds parts layer-by-layer. A thin layer of powder is spread onto a print bed. The inkjet array inside the print carriage makes a sweeping motion over the print bed, releasing two agents downward — a fusing agent and a detailing agent. The fusing agent fuses the powder together. The detailing agent is used to reduce fusing at the part boundary in order to achieve greater detail.

MJF is perfect for projects that require higher density, smooth surfaces, and low porosity. Very little post-production is needed, resulting in much shorter lead times.

What is MJF printing? This technology is quickly becoming a popular choice for 3D printing prototypes and production parts. Ideal uses for MJF are enclosures, electronics housings, complex ducts, lattice structures, and functional assemblies. The technology is capable of 3D printing parts with high detail and suitable for applications that require durability (e.g., snap fits). The MJF process allows for nesting in the z-direction. MJF is just another tool in Fathom’s toolbox, expanding our already comprehensive 3D printing and additive manufacturing service capabilites.

The material currently available for MJF is Nylon 12 (PA 12), a highly durable thermoplastic that is ideal for functional prototyping and low-volume production runs. Nylon 12 allows for smooth surfaces with fine details and strength. It has excellent resistance to oils, grease, aliphatic hydrocarbons, and alkalis. The resulting part is a non-uniform light gray that can be dyed a darker color.

Multi Jet Fusion Advantages / /

- High Detail

- Complex Parts

- Fast Turnaround Times

- Smooth Surfaces

- Minimal Need for Post-Production Finishing

- Durable Production Quality

- Improved Performance

- Low Costs

Multi Jet Fusion Applications / /

- Enclosures

- Electronics Housings

- Complex Ducts

- Wiring Clips

- Guides

- Grommets

- Lattice Structures

- Functional Assemblies

- Prototypes Used for Fit, Form, and Function Tests

- Complex End-Use Parts

MJF Parts In As Soon As 2 Days / / Get A Quote

Selective Laser Sintering (SLS) 3D Printing

What is Selective Laser Sintering (SLS)? SLS technology is commonly used to create models, prototypes, and end-use parts in durable, engineering-grade thermoplastics. SLS can be utilized for larger part quantities. Consider SLS for applications that involve high-complexity and organic geometries, as well as parts requiring durability.

How does Selective Laser Sintering work? SLS uses a blade to spread a thin layer of powder over the build platform. A laser then fuses the powder together, forming a cross section layer of the part. The build platform is lowered one layer and the process begins again until the build is finished. Parts are then excavated from the build powder-cake and bead blasted to remove loose powder. No support removal is necessary since the unused powder in the build envelope acts as the support structures.

Common uses of SLS include functional prototypes, concept models, consumer products, architectural models, electronics housings, medical devices, sculptures, jigs, fixtures, and more.

Selective Laser Sintering Advantages / /

- Does Not Require Support Structures

- Great for Intricate and Complex Geometries

- Fast Turnaround

- Strong Layer Adhesion

- Can Be Dyed

Selective Laser Sintering Applications / /

- Functional Prototypes

- Concept Models

- Electronics Housings

- Medical Devices

- Jigs and Fixtures

SLS Parts In As Soon As 2 Days / / Get A Quote

DMLS 3D Printing

Metal 3D printing, also known as Direct Metal Laser Sintering (DMLS) and Direct Metal Laser Melting (DMLM), is an additive layer technology used to make metal parts. DMLS 3D Printing by Fathom allows designers and engineers to streamline manufacturing with precision metal prototypes and low-volume metal production parts. DMLS is capable of making parts that would be otherwise impractical or cost-prohibitive to machine by conventional methods. Fathom can create metal parts using a fiber laser fired onto a metal plate, repeatedly adding layers of powdered metal, and fusing them to the previous layers. Resulting parts are accurate with excellent surface quality and mechanical properties.

How does DMLS work? A metal 3D printer utilizes a laser beam to melt 20 to 60 micron thick layers of metal powder on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal. The process is like other polymer-based 3D printers that use powder bed fusion.

DMLS Advantages

- Precision

- High-Quality

- Low-Volume

- Strength

DMLS Applications

- Functional Prototypes

- Spare Parts

- Biomedical Implants

- Tooling

DMLS Parts In As Soon As 3 Days / / Get A Quote

3D printing Samples

3D printed samples, in the most commonly used materials, are available for purchase. Check out our 3d printing samples.

Downloads and Additional Resources

View additional downloads and resources in our 3D printing resources section.

Learn about 3D Printing Services at Fathom

Quickly get an INSTANT quote on any 3D printing project today.

| Core Capabilities | 3D Printing and Additive Manufacturing, CNC Machining, Urethane Casting, Tooling & Injection Molding, Finishing & Assembly |

| Additive Technologies | Fused Deposition Modeling (FDM), PolyJet (PJ), Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Direct Metal Laser Sintering (DMLS), Metal 3D Printing |

| Engineering & Design | Fathom’s Team of Designers and Engineers Who Can Support a Company’s In-House Product Development Team Throughout Prototyping and Production Phases |

| Managed Services | Fathom’s Part-Time and Full-Time Staffing Solutions That Enhance Your In-House Fabrication—Fathom Experts Operate Equipment, Manage Work Orders and Much More |

| Additional Services | + Consultation, DFM/DFAM Guidance, Technology and Material Evaluation, Research and Development, etc. |

Related Topics:

- Lattice Structure 3D Printing

- Metal 3D Printing Cost

- Metal 3D Quotes

- Nickel 3D Printing

- Plastic Printing Quotes

- Aluminum 3D Printing

- Titanium 3D Printing

- Steel 3D Printing

- Cobalt Chrome 3D Printing

- Metal 3D Printing Quotes

- Additive Manufacturing FDM

- Additive Manufacturing Polyjet

- Additive Manufacturing SLS