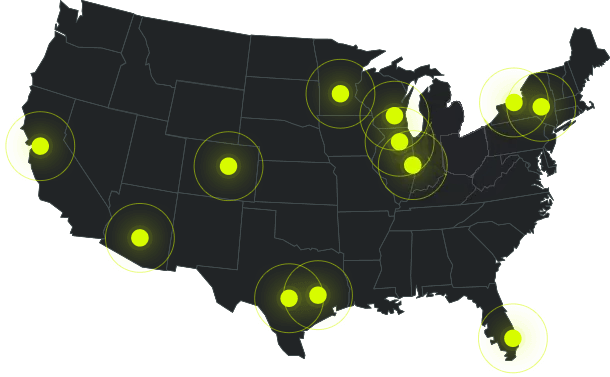

For high-quality polyethylene (PE) parts, partner with an experienced manufacturer. Fathom can meet the requirements of your polyethylene injection molding project whether your job is time-sensitive, requires high precision, or is highly complex or short project run related. Injection molding is just one of many manufacturing technologies offered by Fathom. Get started today.

Polyethylene (PE) is one of the most popular thermoplastic polymers used in manufacturing. PE is used for various applications, from housewares to automotive components. There are multiple grades of polyethylene ranging from high density to low density. High-density polyethylene (HDPE) has a stiff crystalline structure and is used for construction parts. Ultrahigh molecular weight polyethylene (UHMW) is dense with high tensile strength and is often used for high-performance equipment such as bulletproof vests. Low-density polyethylene (LDPE) is flexible and used for packaging such as grocery bags. Linear Low-density polyethylene (LLDPE) is low-density polyethylene that has been blended to add tensile strength and flexibility. LLDPE is used for products such as pond liners.

There are many benefits to injection molding polyethylene. Depending on the grade used, polyethylene can be hard or soft. Polyethylene is lightweight and strong. PE’s chemical resistance increases with its density. High-density polyethylene has greater chemical resistance than low to medium PE.

High-density polyethylene (HDPE) is a widely used grade of polyethylene. HDPE is tough, flexible, and offers good impact resistance. HDPE is suitable for injection molding. Injection molding facilitates greater control over product customization, high repeatability, reduced labor costs, high productivity and the ability to produce thousands of parts from a single mold. If your project calls for a high volume of parts, injection molding is a cost-effective manufacturing process as the cost per part decreases the more parts are produced over time. Chairs, bottle crates, toys, milk jugs and medical parts are all made using injection molded HDPE.

Following injection molding, the part is transitioned to the finishing process. While some finishes are used to alter the appearance of a part, others strengthen its physical properties. Finishes offered by Fathom include:

| SURFACE FINISH | GUIDE | TYPICAL APPLICATIONS |

|---|---|---|

| Standard No Machine Mark | Tool Marks Removed | Low Cosmetic |

| SPI-C1 | 600 Stone | Low Polish Parts |

| SPI-B1 | 600 Grit Paper | Medium Polish Parts |

| SPI-A2 | Grade #6 Diamond | High Polish Parts |

| SPI-A1 | Grade #3 | Lens or Mirror |

| IM-1 Light Bead Blast | Need 1 Degree Draft Angle | |

| IM-2 Medium Bead Blast | Need 1.5 Degree Draft Angle | |

| IM-3 Heavy Bead Blast | Need 3 Degree Draft Angle |

Fathom’s services include injection molding and hybridized services that leverage multiple 3D printing technologies. Do you want to incorporate injection molding into your complex project? Fathom can help. In a recent case study, Fathom delivered over 20,000 parts in 27 days, using 55+ tools, including multiple injection molding services:

A customer came to Fathom with a complex project that spanned the technologies and processes of rapid production—and needed it done fast. Fathom delivered.

55+ Tools to Injection

Mold 15,000 Parts

First Article in 2 Weeks

3,000+ 3D

Printed Parts

2,000+ Metal

Fabricated Parts

3D Printing / Additive Manufacturing—PolyJet, SLS, MJF.

DFM Analysis + CAD Mods.

CNC Machining. Laser Cutting.

Stamping. Die Cutting. Post-Opp Drilling.

24-hour Turnaround Urethane Casting.

Injection + Compression Molding.

Model Finishing. Insert Assembly.

Advanced Project Management.

A: Yes, Fathom offers injection molding services.

A: Injection molding is a manufacturing process commonly used for plastic parts. During injection molding, molten plastic is injected into a two-part mold using high pressure. Once the part has cooled inside the mold, it is ejected. The part may or may not require a secondary finish.

A: Fathom’s certifications include ISO 9001:2015, ISO 9001:2015 Design, and ISO 13485:2016. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom is ITAR certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom is AS9100:2016. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom’s certifications include NIST 800-171. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Polyethylene is a raw material commonly used for manufacturing. Products such as shopping bags, water bottles, and piping are all made using different grades of polyethylene.

A: Yes, polyethylene is suitable for injection molding.

A: Polyethylene is commonly used in injection molding because it can be used to make a wide variety of parts, is cost-effective, and, depending on the grade, can be rigid or soft.

A: High-density polyethylene is a popular material for injection molding. HDPE is used to make everything from milk jugs to medical parts.

Ready for a quote on a polyethylene injection molding project? Do you need to calculate costs? Use Fathom’s SmartQuote application for a fast quote on any file.